Protective Packaging Manufacturer

Ameson has focused on protective packaging industry for more than 18 years, the sales network covers over 60 countries.

About Ameson

One-stop Packaging Supplier

Ameson Packaging was established in 2006, The headquarter is locate in China, the facility has over 70,000 square meters. All the products we sell are patented and manufactured by ourselves. We have many distribution sales network all over the world. In 2016, the Ameson USA established, for better service to the distributor and users in north America market. Our distribution network are over 60 countries, and customers over 90 countries. Thousands of warehouse fulfillments, including Amazon, Alibaba, IBM, etc. are using Ameson’s protective & intelligent packaging services every day. We protect at least millions of packages every day.

Factory Area

Export Experience

Patent & Invention

National Sales Network

Annual Export Amount

Production Lines

Our Partnership

Featured Products

We supply air cushion machine, air bubble & pillow film, paper void fill system, honeycomb paper, foam in place, water activated tape dispenser, air column bags, padded mailer, dunnage bags, biodegradable pallet wrap & strap, sustainable materials, etc.

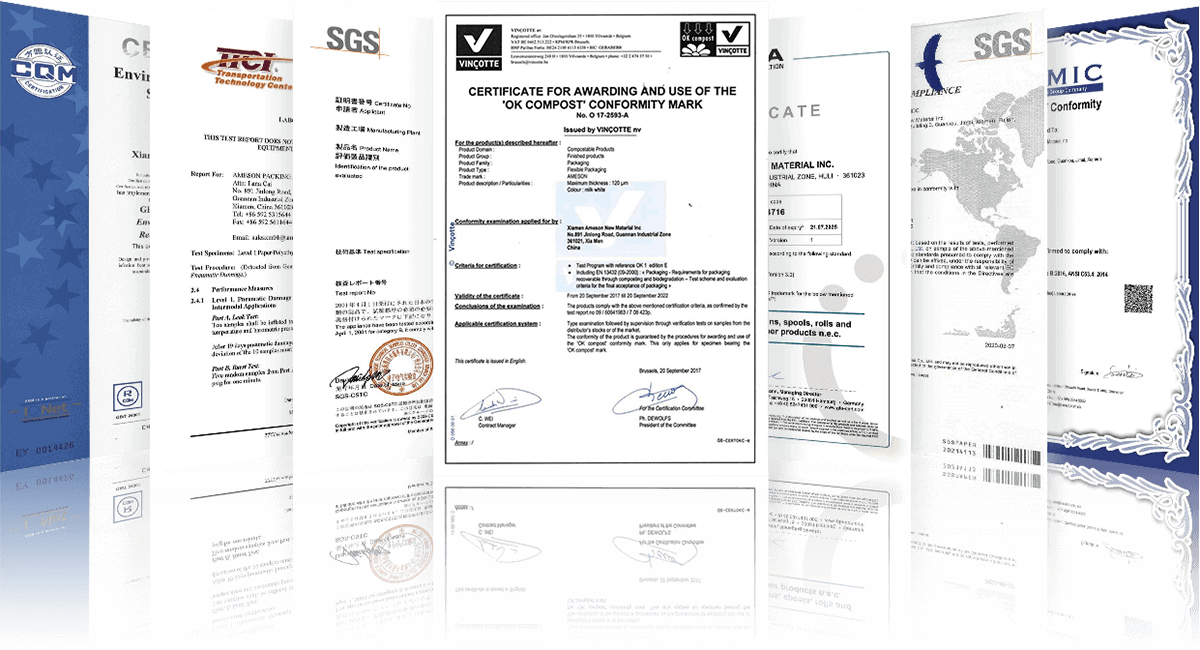

Patent & Certificate

All the products we sell are patented and manufactured by ourselves. Certified: ISO 9001, ISO 14001, ISO 45001, ISO 50001, CE, PSE, UL, GRS, OK compost, etc.